Some Of Alcast Company

Table of ContentsRumored Buzz on Alcast CompanyIndicators on Alcast Company You Should Know10 Easy Facts About Alcast Company ShownAlcast Company for BeginnersAbout Alcast Company4 Simple Techniques For Alcast Company

Chemical Comparison of Cast Aluminum Alloys Silicon advertises castability by minimizing the alloy's melting temperature and improving fluidity during spreading. Additionally, silicon adds to the alloy's stamina and put on resistance, making it beneficial in applications where resilience is essential, such as vehicle components and engine components.It also improves the machinability of the alloy, making it simpler to process into ended up items. This way, iron adds to the total workability of aluminum alloys. Copper increases electrical conductivity, making it beneficial in electrical applications. It additionally boosts rust resistance and contributes to the alloy's general toughness.

Manganese adds to the stamina of aluminum alloys and improves workability. Magnesium is a light-weight component that gives toughness and impact resistance to aluminum alloys.

The 3-Minute Rule for Alcast Company

Zinc boosts the castability of aluminum alloys and aids manage the solidification process during spreading. It enhances the alloy's strength and firmness.

The primary thermal conductivity, tensile stamina, yield strength, and prolongation differ. Among the above alloys, A356 has the highest thermal conductivity, and A380 and ADC12 have the cheapest.

An Unbiased View of Alcast Company

In precision casting, 6063 is well-suited for applications where detailed geometries and top notch surface coatings are paramount. Instances consist of telecommunication enclosures, where the alloy's premium formability enables sleek and cosmetically pleasing styles while keeping architectural honesty. In the Lighting Solutions sector, precision-cast 6063 elements develop elegant and reliable lighting fixtures that require detailed forms and good thermal efficiency.

It brings about a finer surface coating and better rust resistance in A360. Additionally, the A360 displays remarkable elongation, making it excellent for complicated and thin-walled components. In precision spreading applications, A360 is appropriate for markets such as Consumer Electronic Devices, Telecommunication, and aluminum foundry Power Devices. Its improved fluidity enables intricate, high-precision parts like smart device housings and interaction gadget housings.

The smart Trick of Alcast Company That Nobody is Discussing

Its unique properties make A360 a beneficial selection for precision spreading in these industries, improving item durability and top quality. Foundry. Aluminum alloy 380, or A380, is an extensively utilized spreading alloy with several unique characteristics.

In accuracy casting, aluminum 413 radiates in the Customer Electronics and Power Tools sectors. It's generally made use of to craft detailed elements like smart device housings, video camera bodies, and power tool coverings. Its accuracy is exceptional, with limited resistances approximately 0.01 mm, making sure perfect product assembly. This alloy's remarkable rust resistance makes it an outstanding option for exterior applications, guaranteeing resilient, durable products in the mentioned markets.

A Biased View of Alcast Company

Once you have actually determined that the aluminum pass away casting process is suitable for your task, a crucial following action is picking the most suitable alloy. The light weight aluminum alloy you choose will significantly impact both the casting procedure and the residential or commercial properties of the last item. Due to this, you need to make your decision meticulously and take an informed method.

Figuring out the most suitable aluminum alloy for your application will certainly suggest considering a large selection of attributes. The first category addresses alloy features that impact the production process.

The Definitive Guide for Alcast Company

The alloy you choose for die casting directly affects a number of facets of the spreading process, like how easy the alloy is to deal with and if it is susceptible to casting problems. Warm fracturing, also known as solidification fracturing, is a common die spreading flaw for aluminum alloys that can cause interior or surface-level tears or fractures.

Specific light weight aluminum alloys are extra prone to warm cracking than others, and your choice ought to consider this. It can damage both the cast and the die, so you should look for alloys with high anti-soldering residential properties.

Corrosion resistance, which is currently a noteworthy quality of aluminum, can differ considerably from alloy to alloy and is a crucial characteristic to think about depending on the environmental conditions your product will be subjected to (Foundry). Put on resistance is another building commonly sought in aluminum items and can set apart some alloys

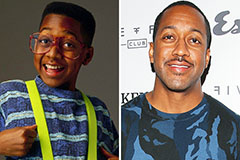

Jaleel White Then & Now!

Jaleel White Then & Now! Judd Nelson Then & Now!

Judd Nelson Then & Now! Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now!